Factories

Promoting health and safety in Accord-covered factories

Regular monitoring, support, incentives, and recognition to make factory safety sustainable.

Text Description

Overview

Bangladesh

Covered Factories: >1680

Pakistan

Covered Factories: >635

Working together for safe workplaces

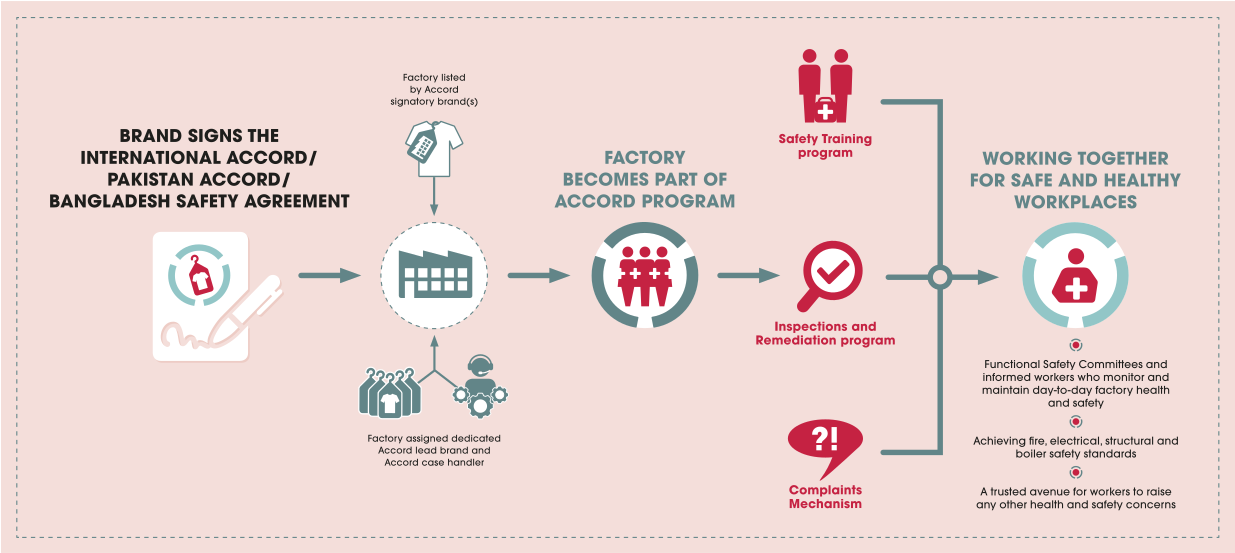

How factories become part of the Accord programs

Reasons to participate

Main title

Body

Main title

Body

Main title

Body

Main title

Body

How factories participate in Accord programs

Independent inspections, timebound Corrective Action Plans, remediation support

Fire safety engineers inspect factories to assess the adequacy of fire prevention, fire containment, early warning systems, and safe egress in case of fire. Remediation often involves establishing and maintaining adequate exit routes, installing certified fire doors, constructing fire-proof separations, and installing, testing, and commissioning a fire alarm system and a fire suppression system.

Structural safety engineers inspect factories to assess the adequacy of engineering assessments, comparison of design drawings with the actual building, and adequacy of load management plans. Remediation often involves conducting a detailed engineering assessment, strengthening vertical or horizontal load-bearing capacity, and maintaining load management plans.

Electrical safety engineers inspect factories to assess the adequacy of cabling and wiring in the factory, the capacity of staff to maintain electrical safety, risk or occurrence of hotspots, and fire risk from the accumulation of dust and lint around electrical components. Remediation often involves developing a Single Line Diagram to depict the electrical scheme of the factory, rewiring to reduce hotspots, training, and Personal Protective Equipment for electrical technicians, and preventing the accumulation of dust and lint around electrical cables.

Boiler safety engineers inspect boilers to assess the condition, installation configuration, safety monitoring system, and operating condition of each boiler in the factory. Remediation often involves addressing calcium build-up, installing an adequate pressure monitoring system, correcting faulty wiring, and developing accurate technical data sheets.

Safety Committee and Safety Training

Joint labour-management Safety Committees undergo a comprehensive training program covering their role in safety management, hazard identification, joint problem-solving, handling complaints, and ongoing safety monitoring.

The Safety Committee and Trainer conduct walk-throughs of the factory to identify actual or potential safety hazards, such as inadequate use of machines, obstacles on the work floor, or poor ventilation or lighting. The Safety Committee supervises remediation of these issues.

During All Employee Meetings, factory production is halted and a presentation is given to every worker and member of management on site. The members of the Safety Committee are introduced to the workforce and information is provided on how to identify and reduce common safety hazards, how to safely evacuate the factory in case of fire or other emergencies, and how to use the Accord Signatories’ Safety & Health Complaints Mechanism. At the end of each meeting, the workers receive a booklet in the local language with the information presented.

Health and Safety Complaints Mechanism

Accord company signatories provide workers at Accord-covered factories with a complaints mechanism and protect them against retaliation for utilising it. The complaints mechanism enables workers and their representatives to raise concerns about health and safety confidentially.

Complaints are investigated and the findings and remediation requirements are announced to all workers in the factory.

Once a complaint is closed, a summary protecting the complainants’ identity is published on the Accord website in the interests of transparency regarding workplace safety.

Views from Accord-covered factories

Body Link Sweater Ltd.

We all want a productive workforce. A safe workplace motivates the workforce to be productive. ACCORD has worked very successfully to make the RMG factories safe. Additionally, ACCORD has helped us with remediation financing while we were struggling. We record our sincere thanks to ACCORD for their all-out support.

Eve Dress-Shirts

After the disaster of 2014, Accord was in action and we became more knowledgeable, informative, transparent, and most importantly accountable. Thus, we can’t thank Accord enough and highly recommend that Accord should cover their regiment across all industries.

Bangla Poshak Limited

Due to Accord programs, we are now a 100% compliance factory. Let me give a little description of how Accord helped us achieve our goal: We were stuck up with our Finance for setting up a Fire detection and Protection system in our factory. So, we needed Accord’s help. Accord has helped us with 75% of the cost freely and arranged another 25% loan from our Buyer without any interest. We are really grateful to them for their help and cooperation.

Inditex

Due to Accord programs, we are now a 100% compliance factory. Let me give a little description of how Accord helped us achieve our goal: We were stuck up with our Finance for setting up a Fire detection and Protection system in our factory. So, we needed Accord’s help. Accord has helped us with 75% of the cost freely and arranged another 25% loan from our Buyer without any interest. We are really grateful to them for their help and cooperation.

Eve-Dress Shirts

After the disaster of 2014, Accord was in action and we became more knowledgeable, informative, transparent, and most importantly accountable. Thus, we can’t thank Accord enough and highly recommend that Accord should cover their regiment across all industries.

For factories undergoing RSC programs in Bangladesh, technical guidelines are available on the RSC website. For other Accord country programs, technical resources will be developed in due course.

Explanation of the Accord’s work and flowchart depicting key steps in each program.

Guidance for factories and signatory companies to plan finance for remediation.