First Safety Inspections Under the Pakistan Accord

The International Accord conducted the first round of initial inspections at factories supplying to Pakistan Accord brands in Lahore and Karachi between 16 – 28 October 2023. These initial inspections mark a significant milestone in the rollout of the Pakistan Accord on Health and Safety in the Textile and Garment Industry (Pakistan Accord) that was established as a new country program under the International Accord in January 2023.

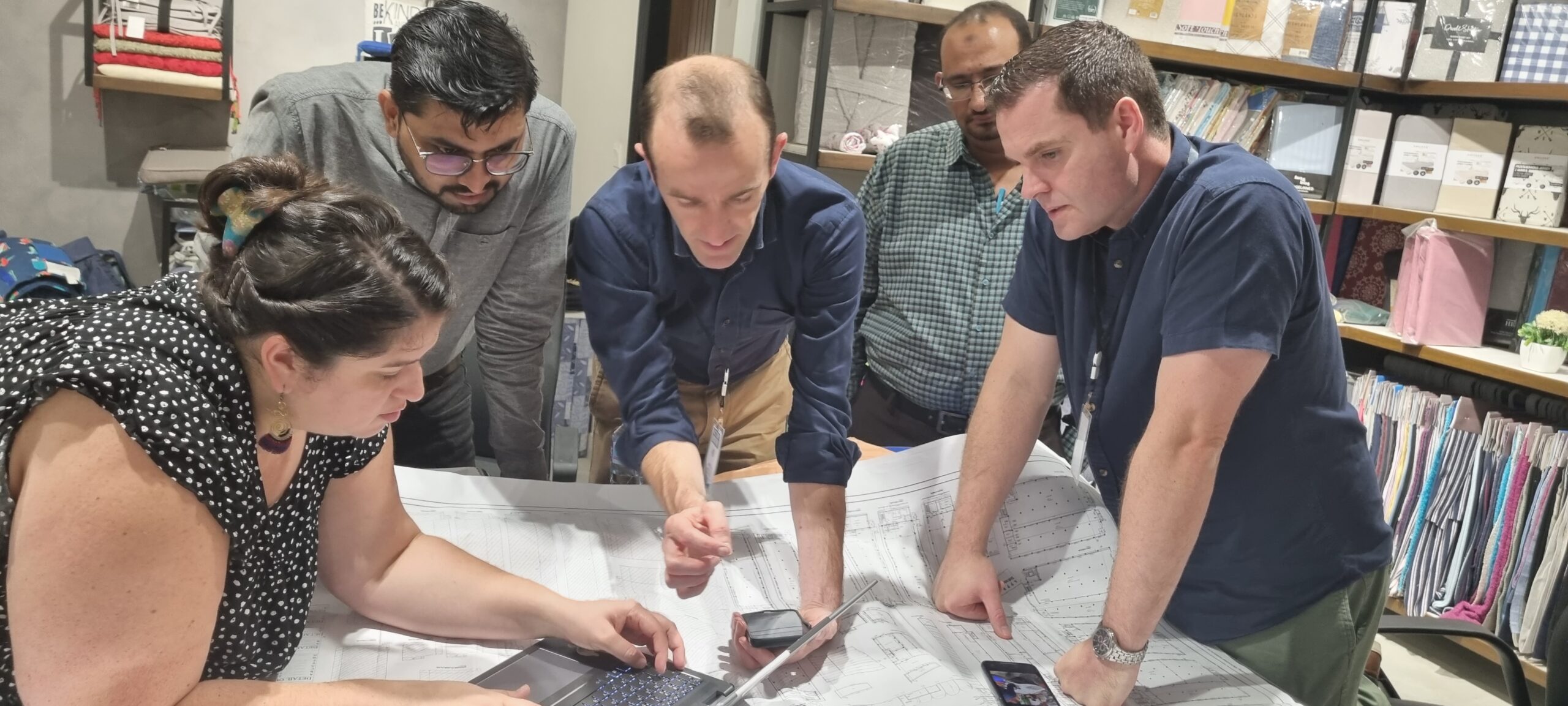

The team, comprising engineers from Arup and representatives from the International Accord, including Danielle Antonellis (Technical Advisor, Pakistan Accord), Brad Loewen (Technical Consultant & Former Chief Safety Inspector of the Bangladesh Accord), assessed fire, electrical and structural safety these supplier factories, based on the Pakistan Accord Building Standard. Zulfiqar Shah (Consultant, Pakistan Accord) and Veronique Camerer (Head of Policy & Accountability, International Accord) joined the team of engineers and conducted side meetings with a number of key local stakeholders.

Participating Factories

The inspections were conducted at four new facilities and four facilities that were part of the pilot safety assessments conducted between November and December 2022. These participating factories demonstrated commitment to ensuring workplace safety, receptiveness to feedback, and preparedness throughout the initial inspection process. These facilities included: E&M Textiles, Mount Fuji Textiles Ltd., Kings Apparel Industries (Pvt) Ltd, Taiga Apparels, Denim Clothing Company, Fashion Knit Industries, Lucky Textile Mills Limited amongst others. We look forward to our ongoing collaboration with these factories and their contribution to ensuring health and safety in the textile and garment industry.

Support from Brands

The Accord brands sourcing from these factories participated actively in the process by communicating their support for the Pakistan Accord and explaining the importance of their suppliers’ participation in the Accord program for continuing their business relationship. Multiple Accord brand representatives also participated in the inspections as observers.

The Inspection Process

Each factory inspection lasted between 1-2 days based on the size and number of buildings and included the following steps:

- Opening meeting with factory owner and technical staff: Introductions & interview with the factory owner

- An overview of the Pakistan Accord program, the process towards developing inspection reports and corrective action plans.

- Review of pre-inspection questionnaire and documentation, such as engineering drawings, Building Permits, calculations, material and systems tests and any reports from previous assessments

- Scheduling & coordination of the fire alarm test

- Inspection of the building exterior and all interior rooms and spaces: 3 separate teams (fire, electrical, structural) inspected the building and assessed fire and building safety of all rooms and spaces.

- Testing: The teams carried out testing as required e.g., ferro-scanning (measuring rebar size in concrete structures), Schmidt Hammer test (measuring concrete strength), thermographic scanning (to identify electrical hotspots). The engineering team also requested the factory team to operate the fire alarm and fire pump systems.

- Closing meeting: Discussion between the Accord team and factory on main observations & next steps.

Next Steps

- Inspection reports will be prepared by the engineers and shared with the factory and Accord brands in 4-6 weeks, varying by complexity.

- Post-inspection meetings with the factories to discuss findings and remediation.

- Development of Corrective Action Plans (CAPs) with the support of Accord brands.

- CAP publication on the Accord website.

Background

Under the Pakistan Accord, all factories supplying to brand signatories will be inspected by independent engineers specialised in fire, structural, electrical, and boiler safety. These engineers assess the factories’ compliance with the Pakistan Accord Building Standard and produce reports of the safety hazards they identify at factories.

The scope of these safety inspections is as follows:

-

- Fire safety: to assess the adequacy of fire prevention, fire containment, early warning systems, and safe egress in case of fire.

- Structural safety: to assess the adequacy of engineering assessments, comparison of design drawings with the actual building, and adequacy of load management plans.

- Electrical safety: to assess the adequacy of cabling and wiring in the factory, capacity of staff to maintain electrical safety, risk or occurrence of hotspots, and fire risk from accumulation of dust and lint around electrical components.

- Hazardous Materials: to assess the use, storage, and handling of chemicals or substances that are classified as a physical hazard material or a health hazard material, whether the chemical or substance is in usable or waste condition.

- Boiler safety: to assess the external and internal condition, installation configuration, and safety monitoring system of each boiler in the factory. Boiler inspections will begin once adequate local capacity to conduct such inspections is achieved.

Resources

Related updates

May 15, 2023

Ten years after the first Accord was signed, the Accord Secretariat reflects on the progress in worker safety in the past decade and our vision for the future.

May 3, 2023

A total of 54 brands and retailers have thus far signed the Pakistan Accord for Health and Safety in the Textile and Garment Industry, with more expected to follow in the coming weeks.

April 24, 2023

The Accord commemorates 10 years since the Rana Plaza collapse by remembering those who perished, those who were injured, and those who continue living with the impacts of one of the worst workplace disasters in modern history.

February 23, 2023

35 signatories to the International Accord have signed the Pakistan Accord to ensure worker safety in the country’s textile and garment industry.

February 18, 2023

The International Accord participated in the 2023 OECD Forum on Due Diligence in the Garment and Footwear Sector held online and offline (Paris, France) from 13-17 February 2023.

February 17, 2023

The International Accord organised a virtual side session on 13 February as a part of the OECD Forum on Due Diligence in the Garment and Footwear Sector to discuss the challenges & opportunities for the recently launched Pakistan Accord.