Identification, Prevention, and Mitigation of Safety Risks Underway in Pakistan

The Pakistan Accord on Health and Safety in the Textile and Garment Industry was established in 2023 with the first batch of initial inspections starting in October 2023. The program is now well underway with fire, electrical and structural safety inspections at 185 factories across Karachi, Lahore and Faisalabad in Pakistan. The Pakistan Accord Workplace Programs were rolled out in August 2024, and the team has now reached a milestone of 100 initial meetings at factories to launch the program.

The safety inspections have identified over 5,500 safety issues, including approximately 2,400 related to electrical safety, 2,200 to fire safety, and 900 to structural integrity.

In response, factories have begun addressing these findings and are collaborating closely with the Pakistan Accord’s engineering and remediation teams to implement safety improvements at their facilities.

Immediate Action for Critical Issues

In cases where Accord engineers identified urgent safety concerns, factories have taken immediate remedial actions. These actions include:

- Load Reduction: In areas with overstressed columns, factories have reduced the load on structures to ensure the structural integrity of the building.

- Electrical Panel Shutdown: Unsafe electrical panels have been shut down to mitigate risks of short circuits caused by electrical hotspots and tangled wires.

Left – Before: Tangled wires, dust in electrical panel; Right – After: Organised wires and clean electrical panel to mitigate short circuit risks

Electrical Safety Remediation

Electrical safety has been identified as the most significant risk at the inspected factories, with over 2,400 findings. Most factory fires are caused by electrical hazards, so remediating these issues is a crucial preventative measure. To address these issues, factories are taking the following steps:

- Thermographic Testing: Independent thermographic surveys are being scheduled to detect overheating components, loose connections, and other faults.

- Repairs and Maintenance: Electrical panels are being assessed to identify sources of abnormal temperatures. Actions include tightening connections, redistributing electrical loads, and replacing faulty components and cables. Additionally, factories are actively minimising combustible materials near electrical panels, a crucial measure for reducing the risk of ignition.

Left – Before: Combustible material near electrical panel; Right – After: Combustible material removed

Fire Safety Remediation Measures

Among the 2,200 fire safety findings, 986 issues are related to means of escape. In response to these findings, factories are:

- Removing Locking Features: Non-compliant locking mechanisms are being removed, and doors are being fitted with easy-to-open mechanisms that comply with NFPA 101 and the Pakistan Accord Building Standard.

- Correcting Door Swing Direction: Exit doors are being replaced or modified to ensure they swing in the direction of escape routes, facilitating smoother evacuations during emergencies.

- Installing Handrails: Factories are installing handrails to ensure safe egress and help people safely exit in case of fire safety accidents.

Left – Before: No handrails; Right – After: Handrails installed

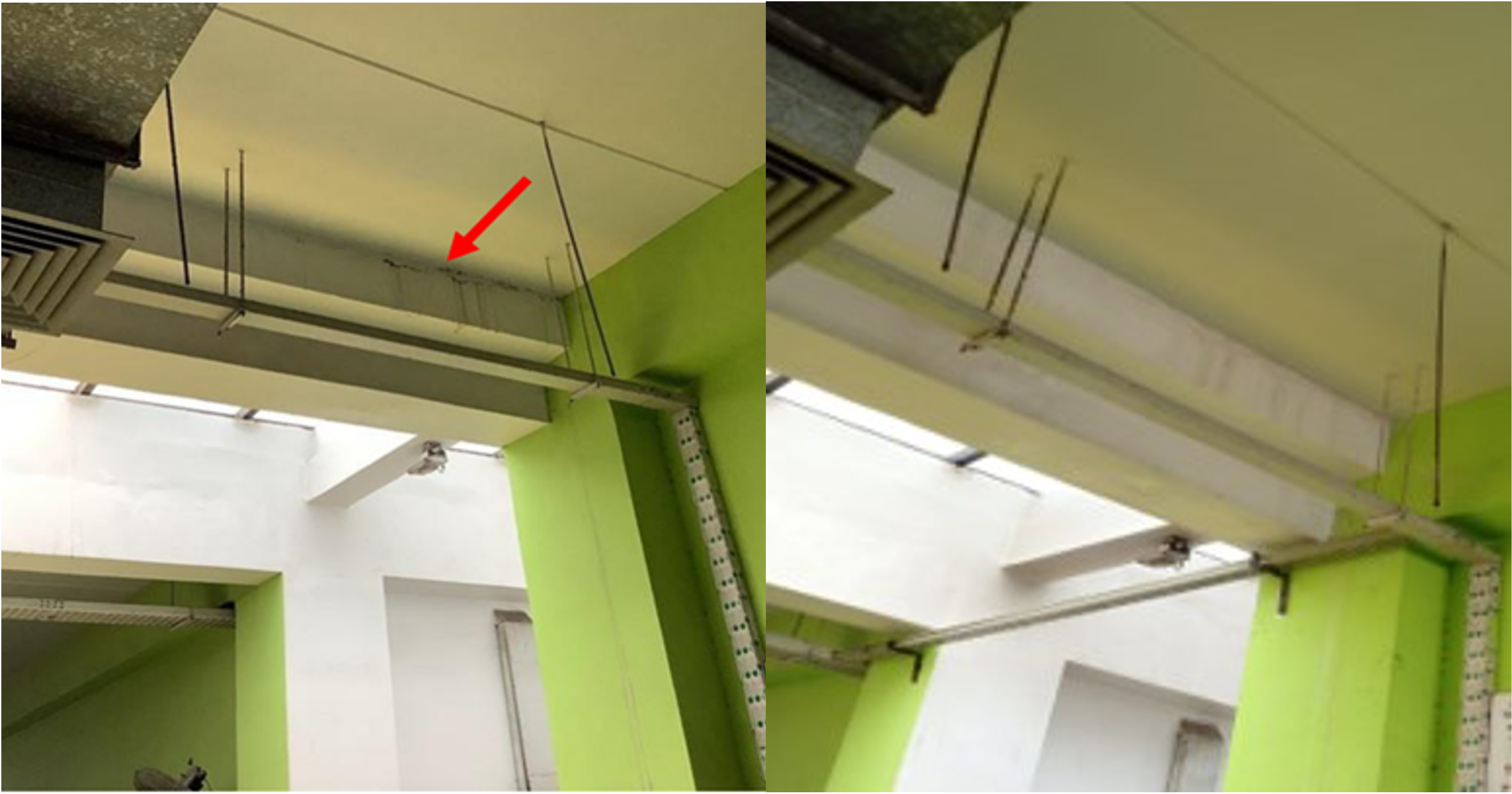

Structural Safety Remediation Measures

Among the 900 structural safety findings, overstressed columns have been a common issue. To mitigate the risks, factories are:

- Reviewing Designs and Loads: Factories are engaging engineering consultants to conduct reviews of design, load distribution, and stress levels on overstressed columns.

- Reducing Loads: Excessive loads are being removed from columns to ensure compliance with the Pakistan Accord Building Standard.

- Fixing Cracks: Factories are fixing building cracks because these repairs help maintain the building’s strength and ensure a safe environment. Addressing cracks early prevents them from developing into larger issues, keeping the structure sound over time.

Left – Before: Cracks in walls; Right – After: Fixed walls

By promptly addressing these safety concerns, factories under the Pakistan Accord are taking important and tangible measures to prevent and mitigate safety hazards within Pakistan’s textile and garment industry. The Pakistan Accord is encouraged by the level of cooperation by suppliers and their commitment to safe workplaces.

The International Accord Secretariat published the first set of Corrective Action Plans (CAPs) and initial inspection reports on fire, electrical, and structural safety for 30 factories under the Pakistan Accord on Friday, 21 February 2025. These reports reflect the safety findings and progress at the inspected factories and are published in accordance with the transparency commitments under the Accord (Section IV, Article 29b of the International Accord, and Section IX, Article 23b of the Pakistan Accord).

The Accord is currently developing a factory search tool to showcase the progress at covered factories in Pakistan. In the meantime, the reports are temporarily available here.

Related updates

February 3, 2026

The parties have agreed to re-sign the Pakistan Accord in its current form, reaffirming their shared commitment to supporting worker health and safety across the supply chains of signatory brands in Pakistan.

January 20, 2026

We extend our deepest condolences to the victims and families affected by the tragic fire at Gul Plaza in Karachi on 17 January.

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

February 3, 2026

The parties have agreed to re-sign the Pakistan Accord in its current form, reaffirming their shared commitment to supporting worker health and safety across the supply chains of signatory brands in Pakistan.

January 20, 2026

We extend our deepest condolences to the victims and families affected by the tragic fire at Gul Plaza in Karachi on 17 January.

November 24, 2025

The International Accord is saddened by the earthquake in Bangladesh and concerned about the reported injuries and loss of life. Our thoughts are with all affected individuals and families.