Supplier Briefing #7

These briefings are designed for all factories and suppliers listed by Pakistan Accord signatory brands. They include updates on key developments under the Pakistan Accord, along with information on upcoming events, guidance materials, and resources for suppliers.

We encourage all suppliers and factories covered by the Pakistan Accord to read these briefings and to share suggestions on what they would like to see in them by contacting us via pakistan.factories@internationalaccord.org.

This briefing includes updates on:

- Coverage: Signatory brands, factories and workers

- Program Rollout: Inspections & Remediation (Update on Boiler Inspections, Common Safety Hazards & Remediation Efforts, Remediation Costing Tool for Factories, Guidance for Factory Engineering Consultants), Workplace Programs (Safety Training, Complaints Mechanism)

- Key Events: Accord All Signatory Meeting 2025

- Implementation: Hiring Updates, Vacancies

Coverage: Signatory Brands, Covered Factories and Workers

At the time of writing this briefing, 138 global brands sourcing from Pakistan have signed the Pakistan Accord and have committed to ensuring workplace health and safety in collaboration with their sourcing partners. Since the last Supplier Briefing, Homefield Apparel, River Island Clothing Co. Limited, WinCraft and Collars & Co. have become signatories.

Pakistan Accord’s signatory brands are headquartered in 18 countries across Europe, the USA, Australia, Hong Kong, Turkey and Japan, and include the world’s largest clothing brands and retailers. Collectively, these brands source over USD $3.5 billion worth of goods from over 645 suppliers in Pakistan employing over 655,000 workers.

View the latest list of Pakistan Accord signatories.

View the list of factories participating in the Pakistan Accord programs.

Program Rollout

Inspections and Remediation

Over 245 factories across Karachi, Lahore, and Faisalabad have been inspected for fire, electrical, and structural safety. Training and capacity-building for the engineering team is ongoing, with the goal of improving turnaround times for producing inspection reports and Corrective Action Plans (CAPs), tailored to the size and complexity of the buildings. Additionally, efforts are focused on enhancing responsiveness to suppliers’ technical queries.

Update on Boiler Safety Inspections

To date, 51 boilers have been visually inspected under the Pakistan Accord’s Boiler Safety program. The Boiler Safety Team commenced inspections in February 2025.

The initial inspection will include both internal and external examinations of the boiler, followed by a hydrostatic test. This process requires the boiler to be shut down and cleaned by the factory beforehand. The boiler must remain shut down to allow the inspections and tests to be completed the following day. Afterward, the factory is responsible for addressing all findings identified during the inspection before the Pakistan Accord boiler engineers return approximately one month later to perform a full functional test.

Once the Boiler Safety Program is fully implemented and the inspection team reaches maximal capacity, the Pakistan Accord will expand the scope to include risk identification of hazardous materials in collaboration with the fire engineering team.

All inspections follow the Pakistan Accord Building Standard and help factories improve safety in Pakistan’s textile and garment industry.

Common Safety Findings and Remediation

The inspected factories are actively working on remediating the following safety hazards:

- Electrical Safety: Common issues include overloaded circuits, improper cable sizing, poor installation, and missing thermographic testing, often leading to undetected hot spots. Many factories also lack accurate Single Line Diagrams (SLDs). To address these, factories are training electrical staff, conducting regular thermographic scans, updating SLDs, and reducing combustible materials near panels to mitigate fire risks.

- Fire Safety: Frequent non-compliance includes locked exit doors or doors that open against escape routes, as well as missing handrails along exits, both of which hinder safe evacuation. Factories are ensuring exit doors open in the direction of escape without locks and are installing handrails to improve safety during emergencies.

- Structural Safety: Overloaded structures from water tanks or added floors, along with visible cracks, pose significant structural safety risks. Factories are reassessing structural loads, reducing stress on key columns, and repairing cracks to ensure long-term building stability.

Remediation Costing Tool for Factories

To strengthen the factories’ ability to plan and manage their remediation efforts effectively, the Pakistan Accord, together with a Lahore-based social compliance consultancy, has developed a Remediation Costing Tool.

This tool is designed to help factories covered under the Accord better estimate and plan for their remediation expenses. By supporting more accurate and realistic budgeting, the tool enables improved remediation planning, helping prevent delays in remediation and avoidable non-compliance issues. The tool draws on average market costs of key safety items identified in a factory’s Corrective Action Plan (CAP), such as fire doors, fire alarms, sprinklers and standpipe systems, and adjusts for cost variations based on factory size.

To ensure its effectiveness, the Remediation Costing Tool will initially be piloted with a small group of factories. Feedback and insights from this phase will inform ongoing refinements, incorporating real-world experience, evolving market data, and user input.Pakistan Accord staff will receive comprehensive training on the tool, with a broader rollout planned in the coming months to make it accessible to all covered factories.

Guidance for Factory Engineering Consultants

Upon the request of covered suppliers in Pakistan, the Accord has development guidance to support factories in identifying and engaging suitably qualified engineers to carry out detailed assessments and remediation efforts detailed in the factory’s Corrective Action Plan.

Through this guidance, the Pakistan Accord aims to facilitate access to reliable expertise, enabling factories to meet the safety requirements outlined in the Pakistan Accord Building Standard and to effectively address their CAP findings. The intent is to ensure that all engaged consultants possess the requisite qualifications, technical expertise, and professional integrity necessary to deliver safe, code-compliant, and high-quality engineering design and advisory services in alignment with the factory’s operational objectives and project-specific requirements.

This initiative is part of the Pakistan Accord’s broader commitment to promoting continuous improvement in workplace safety across Pakistan’s garment and textile sector. The guidance is available here.

Important: Please note that the Pakistan Accord does not accredit or endorse any external consultants. Factories should not hire any outside parties claiming to represent or provide services on behalf of the Pakistan Accord.

Workplace Programs

The Pakistan Accord has made significant progress in its Workplace Programs across factories.

- As of 25 June 2025, initial meetings have been conducted for 204 factories reaching 267,944 workers;

- All-Employee Meetings have taken place at 58 factories—totalling 241 sessions – and 55,653 booklets have been distributed to worker participants.

- Safety Committee Training has been piloted for two factories.

- Information on how to file complaints under the Pakistan Accord Complaints Mechanism has been distributed to 198 factories.

- 85 complaints have been received by the Pakistan Accord Complaints Mechanism of which 58 (68%) were related to Occupational Safety and Health (OSH). The most common types of complaint include: drinking water quality/temperature, injuries/deaths from accidents at work, heat stress, and lack of provision of PPE.

The Workplace Programs are set to expand further, with additional initial and All-Employee Meetings scheduled in the coming months.

Looking ahead, the Workplace Programs will roll out its Safety Committee Training Program and continue to schedule initial meetings and All-Employee Meetings in the coming months. Additionally, key messages will be shared online through animated content.

Recruitment is currently underway in both Karachi and Lahore to strengthen the Workplace Program team, which currently includes four trainers (two based in Karachi and two in Lahore), and a dedicated complaints team comprising three specialists and one Occupational Safety and Health (OSH) manager.

Events

Accord All Signatory Meeting 2025 - May 2025

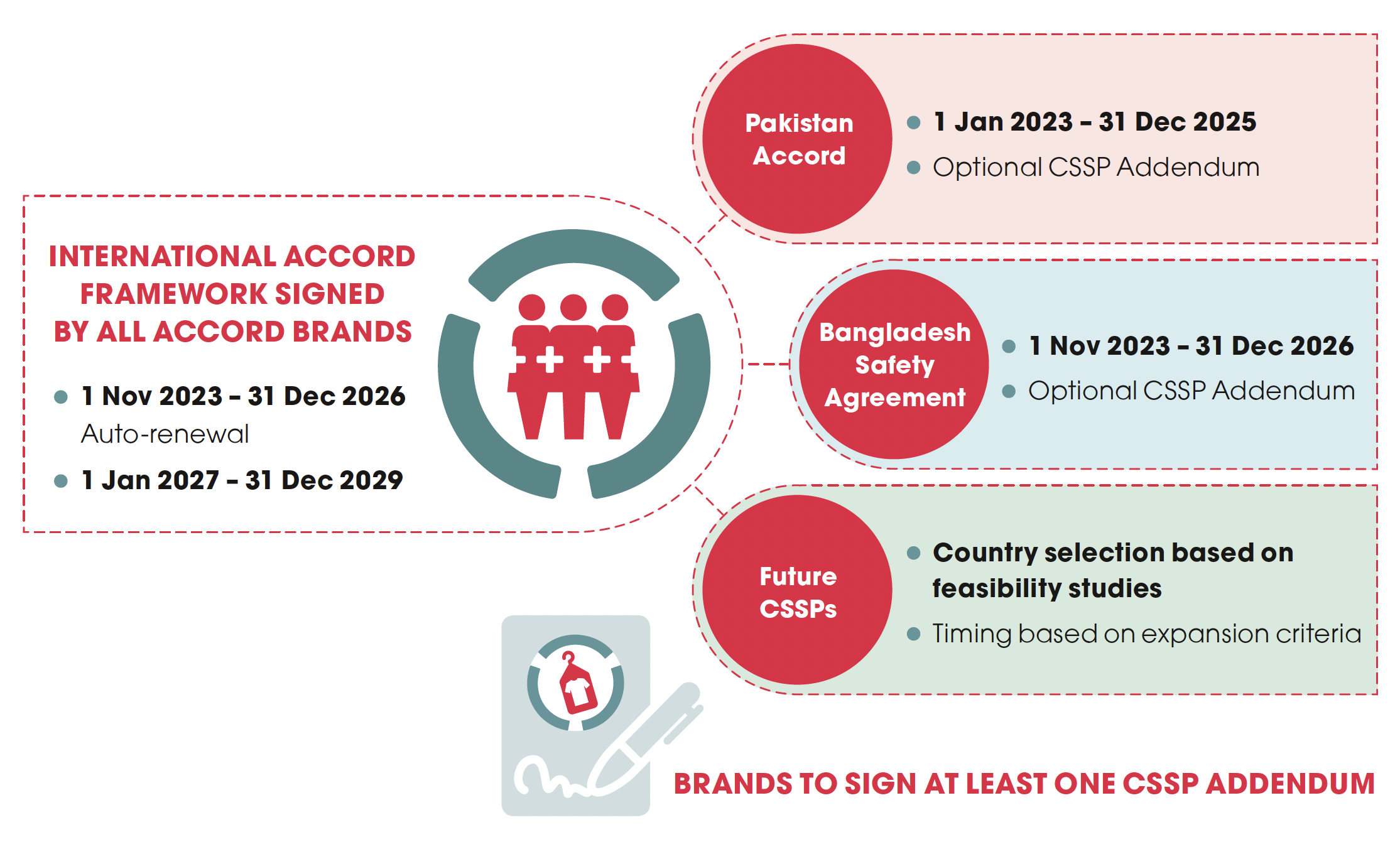

The International Accord held its 2025 All Signatory Meeting in Amsterdam, the Netherlands, bringing together signatory brands, trade unions, and witness signatories. The meeting provided valuable insights into the progress and operations of the Accord’s Country-Specific Safety Programs (CSSPs) in Bangladesh and Pakistan, while also exploring future opportunities to expand the Accord’s scope and impact.

The Accord held its 2025 All Signatory Meeting in Amsterdam, for its brand, trade union, and witness signatories.

Zulfiqar Shah, Country Director of the Pakistan Accord, and Paul Rigby, Chief Safety Officer (CSO), shared insights on the Pakistan Accord’s implementation. They outlined the growing coverage of signatories, factories, and workers under the country program. Shah highlighted the encouraging reception from factories for the worker safety training sessions, as well as the positive feedback received on the government capacity-building program.

Shah highlighting the encouraging reception from factories for the worker safety training sessions and the government capacity-building program.

Rigby provided detailed updates on the factory remediation work underway in Pakistan, including the fire, electrical and structural safety issues at covered factories since the start of inspections in October 2023. He noted overstressed structural columns and a lack of access to safe egress for workers as common safety issues requiring remediation. He further highlighted the ongoing knowledge exchange and collaboration between the engineers from the Pakistan and Bangladesh teams.

Operations

The Pakistan Accord is in the process of building and training local teams in its Karachi and Lahore offices to ensure the effective implementation of its programs in coordination with covered suppliers and brands. The team is continuing to expand the Inspections and Remediation Department as well as the Workplace Programs Department to further implement the programs.

Further recruitment of fire, structural and boiler safety experts, training and complaints specialists, and additional support staff is currently in progress. The latest vacancies under the Pakistan Accord are available on the Accord website.

Resources

Stay in Touch

Related updates

January 25, 2024

Original Marines, Turner Bianca, S.O.K/ Group, Sun Garden,Tex Idea, and MPL Home are among the latest brands to sign the Pakistan Accord.

January 11, 2024

This briefing includes updates on the number of signatory brands, covered factories, Pakistan Accord Building Standard, first inspections under among other topics.

December 12, 2023

Multiple brands are in the final stages of internal reviews and are expected to sign the agreements in the coming days.

December 12, 2023

Multiple brands are in the final stages of internal reviews and are expected to sign the agreements in the coming days.

November 21, 2023

Explore the International Accord framework agreement and its country-specific Addendums, the Bangladesh Safety Agreement, and the Pakistan Accord.

November 20, 2023

The International Accord conducted the first round of initial inspections at factories supplying to Pakistan Accord brands in Lahore and Karachi between 16 – 28 October 2023.