Factory Inspections to Assess Structural Damage from Bangladesh Earthquake

Accord

The International Accord is saddened by the earthquake in Bangladesh and concerned about the reported injuries and loss of life. Our thoughts are with all affected individuals and families.

Our engineering colleagues from the RMG Sustainability Council (RSC) are conducting post-incident inspections at Accord and RSC covered factories where cracks, structural damage, or injuries have been reported and will support the necessary remediation efforts. Ensuring workplace safety remains our highest priority.

We reaffirm every worker’s right to refuse unsafe work and will continue supporting signatory brands in fulfilling their commitments to uphold it. We are closely monitoring the situation and conducting detailed assessments to implement effective safety measures as the situation evolves.

For more information, contact:

Related updates

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

October 22, 2025

This briefing provides updates on the number of signatory brands, factories and workers. Additionally, it includes guidance on the actions suppliers should take to address immediate safety findings.

November 24, 2025

The International Accord is saddened by the earthquake in Bangladesh and concerned about the reported injuries and loss of life. Our thoughts are with all affected individuals and families.

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

Statement: Expansion of the Worker Complaints Mechanism in Bangladesh

Accord

Statement

Amsterdam, 9 November 2025:

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

Originally established under the 2013 Accord on Fire and Building Safety in Bangladesh, the Complaints Mechanism has been implemented by the Ready-Made Garment (RMG) Sustainability Council (RSC) since June 2020. It is implemented in accordance with the principles enshrined in the International Accord Framework Agreement and its country program, the Bangladesh Safety Agreement.

The Complaints Mechanism has become a trusted and effective channel for workers to raise safety and health concerns confidentially or anonymously. Over 4,000 OSH complaints have been filed to date, reflecting the strong trust workers and their representatives place in it.

Workers have raised various safety and health issues in their complaints including denial of maternity benefits, workplace violence and harassment, denial of sick leave, forced overtime, work-related injuries and fatalities. The Complaints Mechanism has provided a range of remedy including reinstatement, maternity payments and leave, disciplinary action, training, sick leave, measures to help prevent forced overtime and compensation payments for occupational injuries and deaths.

While the Complaints Mechanism has successfully delivered remedy for complaints related to safety and health, Accord signatories and stakeholders recognise that many complaints concern other work-related matters that could not be processed under the existing Complaints Mechanism. They have therefore agreed on the value of a unified Complaints Mechanism that addresses all workplace-related complaints and operates in line with the UN Guiding Principles on Business and Human Rights’ criteria for effective non-judicial grievance mechanisms.

In addition to OSH issues, the expanded Complaints Mechanism will cover the ILO Fundamental Principles and Rights at Work, as well as the most common types of complaints including wage payments, overtime, inequitable employment contracts, and severance benefits.

“The expanded scope of the Complaints Mechanism allows the RSC to address a wider range of workers’ concerns on behalf of Accord signatories. We are encouraged by the trust that workers, factories, signatories, and other stakeholders have placed in the Complaints Mechanism over the years and remain committed, alongside our RSC colleagues, to continue to operate with independence, impartiality, integrity and respect for confidentiality,” said Joris Oldenziel, Executive Director, International Accord.

Implementation will be carried out in phases, starting with over 50 signatory brands and 1,000 factories, to ensure a smooth and effective rollout, and subsequently extended to include all covered factories from May 2026. The International Accord, together with the RSC team, signatory brands, and trade unions, will continue to ensure that the Complaints Mechanism remains an accessible and trusted complaints channel for workers.

We extend our appreciation to the RSC Complaints Team for their tireless dedication in operating the Complaints Mechanism, investigating complaints, and delivering timely remedy to workers across covered factories.

We are also grateful to all parties involved, including Accord signatories, trade unions, industry partners, and civil society organisations, for their ongoing collaboration and commitment, which helps to ensure that the Complaints Mechanism continues to operate independently and effectively.

END

Resources

For more information, contact:

Related updates

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

October 22, 2025

This briefing provides updates on the number of signatory brands, factories and workers. Additionally, it includes guidance on the actions suppliers should take to address immediate safety findings.

November 24, 2025

The International Accord is saddened by the earthquake in Bangladesh and concerned about the reported injuries and loss of life. Our thoughts are with all affected individuals and families.

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

Pakistan Accord Brand-Supplier Roundtable Highlights Progress and Collaboration

Accord

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers. The event provided a platform for open dialogue on strengthening cooperation, sharing learnings, and identifying opportunities to enhance occupational safety and health across Pakistan’s textile and garment sector.

In his opening remarks, Michael Bride, Senior VP Corporate Responsibility, Global Affairs at PVH Corp, highlighted brand commitment to Pakistan:

“With over 140 brands now part of the Pakistan Accord, our message to our supplying partners is clear: we believe in Pakistan’s potential and remain committed to investing in the country’s textile and garment industry.”

Brands reaffirmed their trust in the Pakistan Accord to ensure lifesaving safety measures and transparency in monitoring risks — key contributing factors to sustaining and expanding sourcing from Pakistan.

Farhan Nazeer, Manager, Ethical Trade at Marks & Spencer, noted that the presence of the Pakistan Accord has contributed to exploring increased sourcing in the country.

Suppliers echoed this sentiment. Aamir Chottani, CEO of Chottani Industries and Chairman of the Pakistan Readymade Garment Manufacturers and Exporters Association (PRGMEA) South Zone, stated:

“The Accord is a door opener for business to suppliers; it builds confidence for the top management of brands that inspections are conducted independently and transparently.”

A dedicated panel explored how to further strengthen brand-supplier collaboration, featuring:

- Felicity Tapsell, BESTSELLER

- Farhan Nazeer, Marks & Spencer

- Aamir Chottani, Chottani Industries

- Raffay Bin Rauf, Sapphire Finishing Mills

- Farrukh Zaman, Klash Pvt. Ltd

Suppliers commended the Pakistan Accord Secretariat’s work while underscoring the need for greater technical engineering capacity and a clearer return on investment for safety measures. They also called for sustained brand support through stable, long-term business relationships.

Raffay Bin Rauf of Sapphire Finishing Mills emphasised:

“Brands should consider factories as business partners, not just suppliers.”

The Accord extends its gratitude for International Accord Steering Committee members Felicity Tapsell (BESTSELLER) and Michael Bride (PVH), who reaffirmed their commitment to extend the Pakistan Accord into 2026, working together to ensure a safe and sustainable garment and textile industry in Pakistan.

The Roundtable was followed by an internal brand meeting focused on operations and collective efforts to ensure the successful and continued rollout of the Pakistan Accord.

For more information, contact:

- media@internationalaccord.org

- Mini Dixit, Communications Advisor: mini.dixit@internationalaccord.org

Related updates

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

October 22, 2025

This briefing provides updates on the number of signatory brands, factories and workers. Additionally, it includes guidance on the actions suppliers should take to address immediate safety findings.

November 24, 2025

The International Accord is saddened by the earthquake in Bangladesh and concerned about the reported injuries and loss of life. Our thoughts are with all affected individuals and families.

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

Pakistan Accord: Supplier Briefing #8

Supplier Briefing #8

These briefings are designed for all factories and suppliers listed by Pakistan Accord signatory brands. They include updates on key developments under the Pakistan Accord, along with information on upcoming events, guidance materials, and resources for suppliers.

We encourage all suppliers and factories covered by the Pakistan Accord to read these briefings and to share suggestions on what they would like to see in them by contacting us via pakistan.factories@internationalaccord.org.

This briefing includes updates on:

- Coverage: Signatory Brands, Factories and Workers

- Pakistan Accord Renewal & Role of Suppliers

- Program Rollout: Inspections & Remediation (Immediate Findings & Actions), Workplace Programs (Safety Training and Complaints Mechanism)

- Operations

Coverage: Signatory Brands, Covered Factories and Workers

At the time of writing this briefing, 142 global brands and retailers sourcing from Pakistan have signed the Pakistan Accord and have committed to ensuring workplace health and safety in collaboration with their sourcing partners. Since the last Supplier Briefing, Cotton On Australia, Essenza Home, Wolly & Co, and Genuine Collective have become signatories.

Signatory brands are headquartered in 18 countries across Europe, the USA, Australia, Hong Kong, Turkey and Japan, and include the world’s largest clothing brands and retailers. Collectively, these brands source over USD $3.5 billion worth of goods from 659 suppliers in Pakistan employing 706,408 workers.

View the latest list of Pakistan Accord signatories.

View the list of factories participating in the Pakistan Accord programs.

Pakistan Accord Renewal & Role of Suppliers

Negotiations are underway to extend the Pakistan Accord. As Accord representatives work toward renewal, factories are encouraged to continue advancing safety improvements at their facilities in collaboration with their appointed engineering consultants, signatory brands and the Pakistan Accord teams in Karachi and Lahore.

These efforts contribute to overall safety enhancements across Pakistan’s textile and garment industry and strengthen long-term business relationships with global brands and retailers.

Depending on their current stage in the remediation journey, the Pakistan Accord encourages factories to implement the following actions:

Pre-Inspection

- Onboarding Form: Submit administrative details and participation in the Pakistan Accord.

- Initial inspection Scheduling: Confirm time and date with the Pakistan Accord team.

- Pre-inspection Form: Submit all required documentation prior to the initial inspection.

- Pre-inspection Meeting: Understand the inspection and remediation process.

Remediation

- Engage a Qualified Engineering Consultant: Engage a consultant as soon as possible to begin remediation work following your Corrective Action Plan (CAP).

- Confirm Start and End Timings in your CAP:Work with your engineering consultant to review and agree on start and finish dates for each CAP finding. Any request for timeline adjustments must be justified by the consultant.

- Provide Regular Remediation Updates: Submit progress updates at least every four weeks. Your assigned Factory Remediation Coordinator (FRC) will also contact you every 28 days to request updates.

- Support Workplace Programs: Facilitate the rollout of Safety Training and the Complaints Mechanism within your factory.

Finance Planning

- Develop a Remediation Finance Plan: The Pakistan Accord team will assist you in preparing a phased Remediation Finance Plan covering the course of your remediation journey. This plan will provide your factory with financial visibility and prevent remediation delays.

- CAP Tool: A dedicated tool will be made available to assess the investments required to complete remediation measures outlined in your CAP.

The Pakistan Accord team is available to provide general guidance and support on CAP development. Factories are encouraged to work closely with their consulting engineers to ensure the effective implementation of remediation measures and Workplace Programs. Without the involvement of a qualified engineer, a factory will be unable to carry out its CAP.

The Pakistan Accord will organise workshops in the near future for factories and engineers to strengthen technical knowledge and build deeper engineering capacity.

Program Rollout

Inspections and Remediation

To date, over 300 factories across Karachi, Lahore, Sialkot, Multan, and Faisalabad have been inspected for fire, electrical and structural safety.

Immediate Findings

Recent factory fires in Pakistan and Bangladesh, including the tragic incident in Mirpur, Dhaka, which claimed at least 16 workers’ lives, underscore the devastating human cost of inadequate safety measures.

There are several immediate actions factories can take to significantly ensure worker safety, particularly to ensure rapid evacuation in the event of a fire:

Lockable Exits/Collapsible Gates: Remove all locks and mechanisms including bolts and hasps, from exit doors. If locks are necessary for security, use specialised door locking features that comply with NFPA 101.

Left – Hazard: Locked fire exit; Right – Control: Unlocked, self-closing fire exit

Storage in Egress Paths, Exit Stairs & Dining Areas: Implement management systems to keep all egress routes, stairs, and dining areas clear of storage at all times. Stairs must always remain protected and unobstructed.

Left – Hazard: Blocked/narrowed evacuation route; Right – Control: Clear exit route

Stair & Occupant Load Signs: Provide stair designation signs and occupant load signs at the required locations. For stairs that do not lead outside the building, further modifications may be required to qualify as a means of egress. Guidance will be in your CAP or developed by your appointed engineering consultants.

Inadequate Exit Capacity: Specify stair locations, discharge floors, arrangements for discharge to grade, and openings on discharge floors (storage, production, etc.)

Cracked Columns: Have your consulting engineers, witnessed by Pakistan Accord engineers, assess any cracked structural columns.

Left – Hazard: Crumbling columns/cracks; Right – Control: Building maintenance & structural safety assessment

Hot Spots: Inspect electrical load conditions, panel locations, and probable causes of high temperatures. If temperatures are excessive, circuit breakers must be immediately shut down.

Storage of Raw Materials and Finished Goods: Keep all materials away from work areas and heat sources. Order raw materials only as necessary and expedite delivery of finished goods to customers. All items must be kept clear of ignition sources, particularly electrical equipment or heat-producing machinery.

Do not delay addressing these fundamental life-saving measures. For any questions or support, contact the Pakistan Accord engineering team.

In addition to these measures, fire detection systems have important life-saving value as they alert occupants to the presence of a fire and allow them to evacuate safety. Factories without adequate detection systems should post security or other personnel as a temporary “fire watch” to ensure early detection. This in turn will facilitate prompt evacuation of the building before a fire develops.

Sprinkler systems provide a significant life-saving measure and are essential in multiple scenarios depending on the height of the building or large open production floors with extended travel distances. Sprinklers are also a cost-effective remediation measure. Consult your CAP or the Pakistan Accord team for further guidance.

Both fire detection and sprinkler systems, including fire pumps, water reservoirs, and standpipe systems, are complex installations requiring detailed technical design, engineering calculations, professional expertise and investments. Factories should discuss these systems with their engineering consultants as soon as possible.

Guidance for Factory Engineering Consultants

At the request of covered suppliers, the Pakistan Accord has developed guidance to support factories engage qualified engineering professionals for assessments and remediation under their CAPs. View the guidance document here.

The guidance supports factories in meeting the Pakistan Accord Building Standard, ensuring consultants have the qualifications, expertise, and integrity to deliver safe, code-compliant, high-quality engineering services aligned with the safety improvements at factories.

Important: The Pakistan Accord does not accredit or endorse any external consultants. Factories should not hire any outside parties claiming to represent or provide services on behalf of the Pakistan Accord.

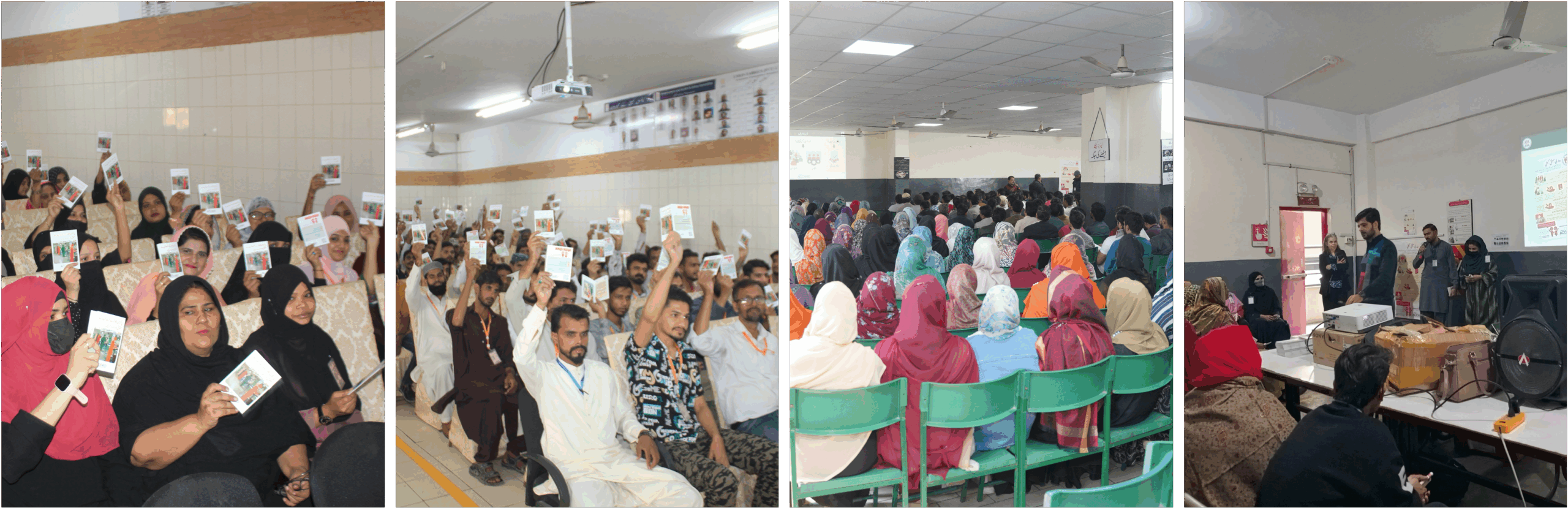

Workplace Programs

The Pakistan Accord has made substantial progress in implementing its Workplace Programs across covered factories, directly reaching 108,358 workers. As of 30 September 2025, 234 initial meetings had been completed, and All Employee Meetings were conducted at 98 factories across a total of 454 sessions.

In addition, 26 Safety Committee meetings have been organised with 310 participants. These joint labour-management committees play a vital role in strengthening workplace health and safety systems for workers across covered factories.

The Pakistan Accord’s Workplace Programs will continue rolling out across all covered factories

The Pakistan Accord Complaints Mechanism has received 167 complaints, with the most common issues including heat stress (drinking water quality and temperature), workplace injuries or deaths and lack of provision of personal protective equipment (PPE).

The Workplace Programs will continue to roll out the Safety Committee Training Program and schedule additional initial and All-Employee Meetings in the coming months.

Operations

The Pakistan Accord is building and training local teams in Karachi and Lahore to ensure effective program implementation. Recruitment is ongoing for:

- Fire, structural, electrical, and boiler safety experts

- Training and complaints specialists

- Additional support staff

Resources

Stay in Touch

Related updates

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

October 22, 2025

This briefing provides updates on the number of signatory brands, factories and workers. Additionally, it includes guidance on the actions suppliers should take to address immediate safety findings.

November 24, 2025

The International Accord is saddened by the earthquake in Bangladesh and concerned about the reported injuries and loss of life. Our thoughts are with all affected individuals and families.

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

Accord Offers Condolences to the Victims of the Mirpur Factory Fire

Accord

The International Accord is deeply saddened by the tragic fire at a garment factory and chemical warehouse in the Shialbari area of Mirpur, Dhaka, which has claimed at least 16 lives and injured many others. Our heartfelt condolences go out to the victims, their families, and all those affected.

This tragedy is a stark reminder of the devastating human cost of inadequate safety measures. Safe exits, unlocked gates, functioning alarms, effective fire separation, and strong emergency preparedness are essential for the safety of every worker, within and beyond the garment industry.

To our knowledge, the affected establishments are not listed by company signatories of the Bangladesh Safety Agreement and not covered by the inspections and remediation program implemented by the RMG Sustainability Council (RSC) in Bangladesh. Nonetheless, this incident underscores the urgent need for comprehensive health and safety measures across all industries.

For over a decade, the collective efforts of brands, trade unions, factories, and civil society partners under the Accord have contributed to workplace health and safety improvements at covered garment and textile factories in Bangladesh. While this includes over 2000 factories employing 2.5 million workers, it represents only part of the Bangladesh’s RMG sector.

Ensuring that every worker has access to a safe working environment must remain a shared priority and responsibility. The Accord and the RSC reaffirm their dedication to working with global brands, industry partners, worker representatives and government authorities to build and maintain a culture of health and safety that prevents such tragedies within the RMG sector in Bangladesh.

The Accord will, together with our colleagues from the RSC, continue to monitor the situation at the affected area and any potential impact on surrounding factories.

END

For more information, contact:

- media@internationalaccord.org

- Mini Dixit, Communications Advisor: mini.dixit@internationalaccord.org

Related updates

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

October 22, 2025

This briefing provides updates on the number of signatory brands, factories and workers. Additionally, it includes guidance on the actions suppliers should take to address immediate safety findings.

November 24, 2025

The International Accord is saddened by the earthquake in Bangladesh and concerned about the reported injuries and loss of life. Our thoughts are with all affected individuals and families.

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

Bangladesh Safety Agreement - Origins

Bangladesh Safety Agreement - Origins

2013 Bangladesh Accord

In 2013, the Accord on Fire and Building Safety in Bangladesh started as a 5-year agreement to pursue workplace safety in the Ready-Made Garment (RMG) sector in Bangladesh.

The agreement was initially signed by 40 brands and retailers, 2 global trade unions, IndustriALL Global Union & UNI Global Union, and 8 Bangladesh trade unions in the immediate aftermath of the April 2013 Rana Plaza building collapse that killed more than 1,000 workers and critically injured thousands more.

2018 Transition Accord

By July 2015, the number of brand signatories had risen to 220 and by May 2018, the joint efforts of Accord stakeholders had significantly contributed to safer workplaces for over 2 million garment factory workers in Bangladesh.

To maintain and expand the achievements of the 2013 Accord, over 190 brands and retailers renewed their commitments by signing the 2018 Transition Accord with the global trade unions. The 2018 Accord ran for 3 years and included a commitment to transition the implementation of Accord programs to a national tripartite organisation now known as the RMG Sustainability Council (RSC).

2021 International Accord

In 2021 the Accord signatories renewed their partnership and established the International Accord for Health and Safety in the Textile and Garment Industry. This agreement confirms the continued commitment of signatories to support workplace safety programs in Bangladesh through cooperation with the RSC and further commits to establishing workplace safety programs in other countries based on the outcome of feasibility studies.

Over 175 company signatories signed the International Accord in the first year of this agreement with an additional commitment to exploring the scope of the agreement to address Human Rights Due Diligence (HRDD) issues in the textile and garment industry.

2023 International Accord and Bangladesh Safety Agreement

In November 2023, brands and trade unions negotiated a new country agreement named the The Bangladesh Agreement on Health and Safety in the Textile and Garment Industry (Bangladesh Safety Agreement) .

The Bangladesh Safety Agreement is a legally binding agreement between garment brands and trade unions to ensure worker health and safety in the Bangladeshi textile and garment industry. The Inspections and Remediation program, Safety Training, the Complaints Mechanism, and reporting and disclosure requirements of the Accord will continue to be implemented in Bangladesh by the RMG Sustainability Council (RSC), which was established in June 2020.

The Bangladesh Safety Agreement is implemented as a country program under the International Accord for Health and Safety in the Garment and Textile Industry (International Accord) framework agreement.

Brands and trade unions renewed their commitments for an extended three-year term, with an automatic renewal of another three years making it the longest Accord commitment to date. This new iteration of the International Accord took effect on 1 November 2023.

The 2023 International Accord serves as a framework for implementing the Accord’s country programs currently in Bangladesh and Pakistan, and future programs in other garment producing countries.

Related updates

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

October 22, 2025

This briefing provides updates on the number of signatory brands, factories and workers. Additionally, it includes guidance on the actions suppliers should take to address immediate safety findings.

November 24, 2025

The International Accord is saddened by the earthquake in Bangladesh and concerned about the reported injuries and loss of life. Our thoughts are with all affected individuals and families.

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

Pakistan Accord - Origins

Pakistan Accord - Origins

Feasibility Assessment for New Country Programs

Following a decision by the Steering Committee under the 2021 International Accord, the Accord Secretariat conducted a feasibility assessment to identify potential new country programs, guided by a defined set of criteria.

The assessment considered factors such as:

- The level of interest among brands;

- The presence and production volume of signatory brands in the country;

- Support from local stakeholders;

- The capacity of existing mechanisms to regulate workplace safety; and

- The potential to enhance health and safety standards in the garment sector.

Between October 2021 and January 2022, the Secretariat conducted brand surveys, desktop research, and in-depth interviews to evaluate brand presence and production trends in key garment-producing countries.

Pakistan as a Priority Country

Pakistan emerged as one of four priority countries identified by signatories for potential Accord expansion. Between March and November 2022, the Accord Secretariat held in-depth consultations with key stakeholders across the prioritised countries, including representatives from industry, government, trade unions, brands, and civil society.

In response to the strong interest expressed by stakeholders in Pakistan, the Accord Steering Committee agreed to move forward with drafting a framework for a potential program in the country. This framework served as a foundation for continued stakeholder engagement and for conducting pilot safety assessments aimed at informing the possible establishment of an inspection and remediation program within the industry.

Establishment of the Pakistan Accord

In December 2022, signatories agreed to establish a new workplace safety program in Pakistan for an initial three-year term, beginning in January 2023. The resulting agreement, the Pakistan Accord on Health & Safety in the Textile & Garment Industry, defines the program’s scope and key provisions to which signatories are committed.

The Pakistan Accord operates as a Country-Specific Safety Program (CSSP) Addendum under the International Accord, renewed in 2023. Initially signed for a three-year period, the agreement includes the prospect of renewal based on program outcomes and continued stakeholder support.

The program will be implemented in close collaboration with Pakistan’s government authorities and the country’s manufacturing industry, ensuring local engagement and shared responsibility for improving workplace safety.

Resources

Stay in Touch

Related updates

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

October 22, 2025

This briefing provides updates on the number of signatory brands, factories and workers. Additionally, it includes guidance on the actions suppliers should take to address immediate safety findings.

November 24, 2025

The International Accord is saddened by the earthquake in Bangladesh and concerned about the reported injuries and loss of life. Our thoughts are with all affected individuals and families.

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

Pakistan Accord: Supplier Briefing #7

Supplier Briefing #7

These briefings are designed for all factories and suppliers listed by Pakistan Accord signatory brands. They include updates on key developments under the Pakistan Accord, along with information on upcoming events, guidance materials, and resources for suppliers.

We encourage all suppliers and factories covered by the Pakistan Accord to read these briefings and to share suggestions on what they would like to see in them by contacting us via pakistan.factories@internationalaccord.org.

This briefing includes updates on:

- Coverage: Signatory brands, factories and workers

- Program Rollout: Inspections & Remediation (Update on Boiler Inspections, Common Safety Hazards & Remediation Efforts, Remediation Costing Tool for Factories, Guidance for Factory Engineering Consultants), Workplace Programs (Safety Training, Complaints Mechanism)

- Key Events: Accord All Signatory Meeting 2025

- Implementation: Hiring Updates, Vacancies

Coverage: Signatory Brands, Covered Factories and Workers

At the time of writing this briefing, 138 global brands sourcing from Pakistan have signed the Pakistan Accord and have committed to ensuring workplace health and safety in collaboration with their sourcing partners. Since the last Supplier Briefing, Homefield Apparel, River Island Clothing Co. Limited, WinCraft and Collars & Co. have become signatories.

Pakistan Accord’s signatory brands are headquartered in 18 countries across Europe, the USA, Australia, Hong Kong, Turkey and Japan, and include the world’s largest clothing brands and retailers. Collectively, these brands source over USD $3.5 billion worth of goods from over 645 suppliers in Pakistan employing over 655,000 workers.

View the latest list of Pakistan Accord signatories.

View the list of factories participating in the Pakistan Accord programs.

Program Rollout

Inspections and Remediation

Over 245 factories across Karachi, Lahore, and Faisalabad have been inspected for fire, electrical, and structural safety. Training and capacity-building for the engineering team is ongoing, with the goal of improving turnaround times for producing inspection reports and Corrective Action Plans (CAPs), tailored to the size and complexity of the buildings. Additionally, efforts are focused on enhancing responsiveness to suppliers’ technical queries.

Update on Boiler Safety Inspections

To date, 51 boilers have been visually inspected under the Pakistan Accord’s Boiler Safety program. The Boiler Safety Team commenced inspections in February 2025.

The initial inspection will include both internal and external examinations of the boiler, followed by a hydrostatic test. This process requires the boiler to be shut down and cleaned by the factory beforehand. The boiler must remain shut down to allow the inspections and tests to be completed the following day. Afterward, the factory is responsible for addressing all findings identified during the inspection before the Pakistan Accord boiler engineers return approximately one month later to perform a full functional test.

Once the Boiler Safety Program is fully implemented and the inspection team reaches maximal capacity, the Pakistan Accord will expand the scope to include risk identification of hazardous materials in collaboration with the fire engineering team.

All inspections follow the Pakistan Accord Building Standard and help factories improve safety in Pakistan’s textile and garment industry.

Common Safety Findings and Remediation

The inspected factories are actively working on remediating the following safety hazards:

- Electrical Safety: Common issues include overloaded circuits, improper cable sizing, poor installation, and missing thermographic testing, often leading to undetected hot spots. Many factories also lack accurate Single Line Diagrams (SLDs). To address these, factories are training electrical staff, conducting regular thermographic scans, updating SLDs, and reducing combustible materials near panels to mitigate fire risks.

- Fire Safety: Frequent non-compliance includes locked exit doors or doors that open against escape routes, as well as missing handrails along exits, both of which hinder safe evacuation. Factories are ensuring exit doors open in the direction of escape without locks and are installing handrails to improve safety during emergencies.

- Structural Safety: Overloaded structures from water tanks or added floors, along with visible cracks, pose significant structural safety risks. Factories are reassessing structural loads, reducing stress on key columns, and repairing cracks to ensure long-term building stability.

Remediation Costing Tool for Factories

To strengthen the factories’ ability to plan and manage their remediation efforts effectively, the Pakistan Accord, together with a Lahore-based social compliance consultancy, has developed a Remediation Costing Tool.

This tool is designed to help factories covered under the Accord better estimate and plan for their remediation expenses. By supporting more accurate and realistic budgeting, the tool enables improved remediation planning, helping prevent delays in remediation and avoidable non-compliance issues. The tool draws on average market costs of key safety items identified in a factory’s Corrective Action Plan (CAP), such as fire doors, fire alarms, sprinklers and standpipe systems, and adjusts for cost variations based on factory size.

To ensure its effectiveness, the Remediation Costing Tool will initially be piloted with a small group of factories. Feedback and insights from this phase will inform ongoing refinements, incorporating real-world experience, evolving market data, and user input.Pakistan Accord staff will receive comprehensive training on the tool, with a broader rollout planned in the coming months to make it accessible to all covered factories.

Guidance for Factory Engineering Consultants

Upon the request of covered suppliers in Pakistan, the Accord has development guidance to support factories in identifying and engaging suitably qualified engineers to carry out detailed assessments and remediation efforts detailed in the factory’s Corrective Action Plan.

Through this guidance, the Pakistan Accord aims to facilitate access to reliable expertise, enabling factories to meet the safety requirements outlined in the Pakistan Accord Building Standard and to effectively address their CAP findings. The intent is to ensure that all engaged consultants possess the requisite qualifications, technical expertise, and professional integrity necessary to deliver safe, code-compliant, and high-quality engineering design and advisory services in alignment with the factory’s operational objectives and project-specific requirements.

This initiative is part of the Pakistan Accord’s broader commitment to promoting continuous improvement in workplace safety across Pakistan’s garment and textile sector. The guidance is available here.

Important: Please note that the Pakistan Accord does not accredit or endorse any external consultants. Factories should not hire any outside parties claiming to represent or provide services on behalf of the Pakistan Accord.

Workplace Programs

The Pakistan Accord has made significant progress in its Workplace Programs across factories.

- As of 25 June 2025, initial meetings have been conducted for 204 factories reaching 267,944 workers;

- All-Employee Meetings have taken place at 58 factories—totalling 241 sessions – and 55,653 booklets have been distributed to worker participants.

- Safety Committee Training has been piloted for two factories.

- Information on how to file complaints under the Pakistan Accord Complaints Mechanism has been distributed to 198 factories.

- 85 complaints have been received by the Pakistan Accord Complaints Mechanism of which 58 (68%) were related to Occupational Safety and Health (OSH). The most common types of complaint include: drinking water quality/temperature, injuries/deaths from accidents at work, heat stress, and lack of provision of PPE.

The Workplace Programs are set to expand further, with additional initial and All-Employee Meetings scheduled in the coming months.

Looking ahead, the Workplace Programs will roll out its Safety Committee Training Program and continue to schedule initial meetings and All-Employee Meetings in the coming months. Additionally, key messages will be shared online through animated content.

Recruitment is currently underway in both Karachi and Lahore to strengthen the Workplace Program team, which currently includes four trainers (two based in Karachi and two in Lahore), and a dedicated complaints team comprising three specialists and one Occupational Safety and Health (OSH) manager.

Events

Accord All Signatory Meeting 2025 - May 2025

The International Accord held its 2025 All Signatory Meeting in Amsterdam, the Netherlands, bringing together signatory brands, trade unions, and witness signatories. The meeting provided valuable insights into the progress and operations of the Accord’s Country-Specific Safety Programs (CSSPs) in Bangladesh and Pakistan, while also exploring future opportunities to expand the Accord’s scope and impact.

The Accord held its 2025 All Signatory Meeting in Amsterdam, for its brand, trade union, and witness signatories.

Zulfiqar Shah, Country Director of the Pakistan Accord, and Paul Rigby, Chief Safety Officer (CSO), shared insights on the Pakistan Accord’s implementation. They outlined the growing coverage of signatories, factories, and workers under the country program. Shah highlighted the encouraging reception from factories for the worker safety training sessions, as well as the positive feedback received on the government capacity-building program.

Shah highlighting the encouraging reception from factories for the worker safety training sessions and the government capacity-building program.

Rigby provided detailed updates on the factory remediation work underway in Pakistan, including the fire, electrical and structural safety issues at covered factories since the start of inspections in October 2023. He noted overstressed structural columns and a lack of access to safe egress for workers as common safety issues requiring remediation. He further highlighted the ongoing knowledge exchange and collaboration between the engineers from the Pakistan and Bangladesh teams.

Operations

The Pakistan Accord is in the process of building and training local teams in its Karachi and Lahore offices to ensure the effective implementation of its programs in coordination with covered suppliers and brands. The team is continuing to expand the Inspections and Remediation Department as well as the Workplace Programs Department to further implement the programs.

Further recruitment of fire, structural and boiler safety experts, training and complaints specialists, and additional support staff is currently in progress. The latest vacancies under the Pakistan Accord are available on the Accord website.

Resources

Stay in Touch

Related updates

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

October 22, 2025

This briefing provides updates on the number of signatory brands, factories and workers. Additionally, it includes guidance on the actions suppliers should take to address immediate safety findings.

November 24, 2025

The International Accord is saddened by the earthquake in Bangladesh and concerned about the reported injuries and loss of life. Our thoughts are with all affected individuals and families.

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

Recap: Accord All Signatory Meeting 2025

Accord

The International Accord held its 2025 All Signatory Meeting on 21 May at Hotel Casa in Amsterdam, the Netherlands. The meeting offered valuable insights into the progress and operations of the Accord’s Country-Specific Safety Programs (CSSPs) in Bangladesh and Pakistan, while exploring future opportunities for expanding the Accord’s scope and impact.

The event brought together over 120 participants from key stakeholder groups, including brand, trade union, and NGO signatories. It also welcomed colleagues from the RMG Sustainability Council (RSC) and the Pakistan Accord Secretariat.

The day commenced with opening remarks from Joris Oldenziel, Executive Director of the International Accord. He welcomed attendees and reflected on the broader socio-political and legislative developments affecting the global textile and garment industry.

Oldenziel noted that, despite ongoing global challenges, the Accord continues to gain momentum. He highlighted that the International Accord and its Bangladesh country program have reached a historic milestone—achieving the highest number of signatories to date.

Updates on the Pakistan Accord

Zulfiqar Shah, Country Director of the Pakistan Accord, and Paul Rigby, Chief Safety Officer (CSO), shared insights on the Pakistan Accord’s implementation. They outlined the growing coverage of signatories, factories, and workers under the country program. Shah highlighted the encouraging reception from factories for the worker safety training sessions, as well as the positive feedback received on the government capacity-building program.

Rigby provided detailed updates on the factory remediation work underway in Pakistan, including the fire, electrical and structural safety issues at covered factories since the start of inspections in October 2023. He noted overstressed structural columns and a lack of access to safe egress for workers as common safety issues requiring remediation.

He further highlighted the ongoing knowledge exchange and collaboration between the engineers from the Pakistan and Bangladesh teams.

Rigby underscored the importance of engagement between brands, retailers and suppliers. He urged brands and retailers to be closely involved in the inspection and remediation process, stressing that proactive collaboration enables more effective risk identification, accelerates remediation timelines, and fosters stronger relationships with factories.

Updates on the Bangladesh Safety Agreement

Abdul Haque, Managing Director of RSC, along with Shah Sefat Uddin Ahmed, Senior Head of the Remediation Program, and MD Hassan Nawazis, Chief Safety Officer (CSO), shared updates and insights into the ongoing health and safety efforts under the Bangladesh Safety Agreement.

The team outlined several key measures aimed at strengthening remediation efforts at covered factories in Bangladesh. These include:

- Capacity-building workshops for factories and service providers

- Clear communication of remediation requirements following inspections

- Introduction of Stage 1 meetings to address non-compliances promptly

Updates included progress on inspection scopes at covered factories and the expansion of the Occupational Safety and Health (OSH) Complaints Mechanism, and the planned digitalisation to streamline organisational processes.

Perspectives on the Complaints Mechanism

Kirstine Drew, Chief Complaints Officer for the Pakistan Accord, and Ovijit Mutsuddi, Head of the Occupational Safety and Health (OSH) Complaints Mechanism Department at the RSC, presented comparative insights from Bangladesh and Pakistan on the Accord’s Complaints Mechanism.

- Drew and Mutsuddi emphasised the core principles that define the Accord’s Complaints Mechanism—accessibility, legitimacy, confidentiality, enforceability and transparency. They also emphasised the dual role of a complaints mechanism – providing access to remedy for workers as well as information that brands and retailers can use to identify and prevent adverse impacts as part of their HRDD. They provided perspectives on both roles.

- They discussed the nature of complaints received and highlighted the differences between Bangladesh’s more mature system and the relatively nascent system in Pakistan. They also provided a breakdown of OSH versus non-OSH complaints, noting that the Accord’s Mechanism currently covers OSH-related issues.

- Mutsuddi shared data and analysis from Bangladesh. Common OSH-related complaints include maternity rights violations, workplace violence, sickness, and forced overtime. While non-OSH complains often involve issues such as wages, benefits and leave entitlements, and unfair terminations.

- Drew offered early-stage observations from the Pakistan Accord, describing a nascent system, with a smaller data set and a more dynamic and fluctuating distribution of complaints. OSH-related issues in Pakistan include forced overtime, workplace injuries, lack of drinking water, and insufficient personal protective equipment (PPE). Non-OSH complaints typically involve non-payment of wages and overtime, especially for contract workers.

A dynamic Q&A session followed, featuring insights from Lena Peleikis, Head of Human Rights & Responsible Supply Chain at the Otto Group, and Christina Hajagos-Clausen, Director of the Textile and Garment Industry at IndustriALL. They discussed the strategic role brands and trade unions can play in strengthening the Mechanism.

The session explored the potential for expanding the scope of the Complaints Mechanism beyond OSH. It also provided suggestions on how brands and retailers can more effectively collaborate in using the data from the Accord Complaints Mechanism for identifying risks and preventing adverse impacts, including by using the structures of the Accord.

Rotating Breakout Sessions

Following the lunch break, smaller participant groups engaged in three rotating breakout sessions:

- Launch of the Accord Signatory Portal: Led by Adelia Arista (Data Analysis & Systems Coordinator) and Colm Quinn (Head of Operations), this session introduced the new internal portal designed for Pakistan Accord signatories as part of the Accord’s broader digital transition. Arista demonstrated key functionalities of the portal and explained how it streamlines access to information about factory progress in Pakistan for signatories.

- Factory Disclosure under the Accord: Facilitated by Koen Oosterom (Head of Signatory Engagement), this session focused on the factory disclosure process under the Accord. Oosterom outlined the requirements and process for signatories to list factories under the Accord, emphasising its central role in ensuring supply chain transparency and accountability.

- External Session by ILO: Employment Injury Scheme Pilot in Bangladesh: Hosted by Dr. Anne Marie La Rosa (ILO), this session explored ILO’s Employment Injury Scheme Pilot in Bangladesh. Dr. La Rosa presented the business case for responsible supply chains, highlighting how the pilot supports worker protections and improves supply chain monitoring for brands.

Accord Expansion, Pakistan Accord Renewal and Brand Caucus

Following the breakout sessions, Oldenziel presented insights into the expansion of the Accord to other countries. The session provided an opportunity for signatories to discuss their interest in expanding the Accord’s work, informed by key findings from a brand survey conducted in March 2025.

The survey results included details on major sourcing countries, the types of supplier facilities involved and priority countries for potential expansion.

In recognition of the need for continued work in Pakistan, brands and trade unions engaged in a discussion around the upcoming negotiations and renewal of the Pakistan Accord. The session focused on the key considerations necessary to ensure the continuity and further strengthening of the Accord’s commitments in Pakistan.

On 22 May, Accord signatory brands convened a Brand Caucus to discuss important topics among peers. Discussions covered the renewal of the Pakistan Accord, the potential expansion of the Complaints Mechanism to address non-OSH grievances, and the Accord’s expansion to other countries.

We extend our sincere thanks to all attendees for their openness, insights, and recommendations, which are critical to effectively implementing the Accord’s programs and contributing to a safer and more responsible garment and textile industry. We also thank our moderator, Olivia Windham Stewart, and the Hotel Casa team for their invaluable organisational support in making this event possible.

For more information, contact:

- media@internationalaccord.org

- Mini Dixit, Communications Advisor: mini.dixit@internationalaccord.org

Related updates

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

October 22, 2025

This briefing provides updates on the number of signatory brands, factories and workers. Additionally, it includes guidance on the actions suppliers should take to address immediate safety findings.

November 24, 2025

The International Accord is saddened by the earthquake in Bangladesh and concerned about the reported injuries and loss of life. Our thoughts are with all affected individuals and families.

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

Pakistan Accord: Supplier Briefing #6

Supplier Briefing #6

These briefings are designed for all factories and suppliers listed by Pakistan Accord signatory brands. They include updates on key developments under the Pakistan Accord, along with information on upcoming events, guidance materials, and resources for suppliers.

We encourage all suppliers and factories covered by the Pakistan Accord to read these briefings and to share suggestions on what they would like to see in them by contacting us via pakistan.factories@internationalaccord.org.

This briefing includes updates on:

- Coverage: Signatory brands, factories and workers

- Program Rollout: Inspections and Remediation, Workplace Programs

- Key Events: Government capacity building sessions, technical workshops for service providers

- Implementation: Hiring update, vacancies

Number of Signatory Brands, Covered Factories and Workers

At the time of writing this briefing, 133 global brands sourcing textiles and garments from Pakistan have signed the Pakistan Accord and committed to working with their suppliers to ensure workplace health and safety. Since the last Briefing, new brands including Levi Strauss & Co., GearCo (Unrivaled Teamwear) and Lomotex GmbH & Co. KG have become signatories.

The Pakistan Accord signatory brands are headquartered in 18 countries across Europe, the USA, Australia, Hong Kong, Turkey and Japan, and include some of the world’s largest clothing brands and retailers. Collectively, these brands source approximately US$3.5 billion worth of goods from over 530 suppliers in Pakistan employing over 567,000 workers.

View the latest list of Pakistan Accord signatories.

View the list of factories participating in the Pakistan Accord programs.

Program Rollout

Inspections and Remediation

Over 200 factories across Karachi, Lahore, and Faisalabad have been inspected for fire, electrical, and structural safety. All inspections follow the Pakistan Accord Building Standard to identify risks and improve safety in Pakistan’s textile and garment industry. Inspections will include the identification of risks linked to hazardous materials at a later stage.

Start of Boiler Safety Inspections

The Pakistan Accord boiler safety team is now fully trained and has conducted seven visual inspections. All factories inspected for boiler safety receive a form to provide details on the quantity and types of boilers at their facilities, ensuring a comprehensive approach to these inspections.

In November 2024, the safety compliance consultancy TUV SUD conducted a week-long training program in Sri Lanka for the Pakistan Accord boiler safety team. As a follow-up, these engineers visited the RMG Sustainability Council (RSC) boiler safety team in Bangladesh for a knowledge exchange session and participated in factory inspections for hands-on training.

Boiler safety engineers from the Pakistan Accord team and the RMG Sustainability Council (RSC) participating in a training session in Sri Lanka.

Inspection Reports and CAPs

The International Accord Secretariat published the first set of Corrective Action Plans (CAPs) and initial inspection reports on fire, electrical, and structural safety for 30 factories under the Pakistan Accord on Friday, 21 February 2025.

These reports reflect the safety findings and progress at the inspected factories and are published in accordance with the transparency commitments under the Accord (Section IV, Article 29b of the International Accord, and Section IX, Article 23b of the Pakistan Accord).

The Accord is currently developing a factory search tool to showcase the progress at covered factories in Pakistan. In the meantime, the reports are temporarily available here.

Common Safety Findings and Remediation

To date, safety inspections have so far identified over 5,500 safety risks, including approximately 2400 findings on electrical safety, 2200 on fire safety, and 900 on structural safety. Below is an overview of the main findings under each safety inspection scope, along with remediation actions factories are taking to improve safety at their facilities.

Electrical Safety

Common findings

Pakistan Accord engineers identified electrical safety as the top risk in inspected factories, with over 2,400 risks. About 1,021 involve distribution boards and protection systems, commonly affected by hot spots from overloading, incorrect cable sizing, and poor installation—issues often missed due to a lack of thermographic testing. Many factories also have incomplete or missing electrical Single Line Diagrams (SLDs).

Remediation

Factories are training electrical staff, implementing thermographic testing for early fault detection, updating SLDs for better troubleshooting, and minimising combustible materials near electrical panels to reduce fire risks.

Left – Before: Combustible material near electrical panel; Right – After: Combustible material removed

Fire Safety

Common findings

Among 2,200 fire safety risks in inspected factories, 986 involve unsafe escape routes. Non-compliance includes locked doors or doors opening against escape routes, hindering evacuation. Many factories also lack handrails on exit routes, increasing risk during emergencies.

Remediation

According to the Pakistan Accord Building Standard, compliant escape doors should be free of locking devices, and swing open in the direction of an escape route. In addition, factories are installing handrails to ensure safe egress and help workers safely exit in case of fire safety accidents.

Left – Before: No handrails; Right – After: Handrails installed

Structural Safety

Common findings

Among 900 structural safety risks, overstressed columns are a major concern, with 188 reported cases. Excessive loads, such as water tanks and floor build-ups, often exceed design capacity, increasing the risk of collapse. Additionally, many factories have cracks in their buildings, further compromising workplace safety.

Remediation

The Pakistan Accord Building Standard and Accord engineers recommend reviewing designs, assessing loads, and reducing excessive stress on columns in high-risk areas to ensure safety. Factories are repairing building cracks to maintain structural strength and prevent them from worsening, ensuring long-term safety.

Left – Before: Cracks in walls; Right – After: Fixed walls

Workplace Programs

The Pakistan Accord has made significant progress in its Workplace Programs across factories.

- In November, the Pakistan Accord conducted its first All Employee Meeting at a home textile factory in Karachi.

- As of the end of February, initial meetings have been conducted at 129 factories, while All-Employee Meetings have been organised at 21 factories, totalling 73 sessions and reaching over 18,500 workers.

- The Safety Committee Training has been piloted at one factory, and the contact details to file complaints under the Pakistan Accord Complaints Mechanism have been distributed to 121 factories.

Looking ahead, the Workplace Programs are set to expand further, with additional initial and All-Employee Meetings scheduled from February through April. Concurrently, the key messages will be communicated online via animations.

Recruitment efforts in Karachi and Lahore are underway to strengthen the Workplace Program team, which currently comprises four trainers—two based in Karachi and two in Lahore—and a dedicated complaints team consisting of two specialists and one Occupational Safety and Health (OSH) manager.

The Workplace Programs are set to expand further, with additional initial and All-Employee Meetings scheduled in the coming months.

Events

Technical Workshops for Service Providers - December 2024

In December 2024, the Pakistan Accord Secretariat hosted two technical workshops for consultants in Lahore (December 12) and Karachi (December 16). Focused on the first 30 factories with technically approved CAPs that have commenced remediation, these sessions aimed to clarify the design documentation and certification requirements for fire, structural, and electrical safety.

The workshops featured insights from Country Director Zulfiqar Shah and Chief Safety Officer George Faller, and included in-depth presentations on Fire Alarm & Detection Systems, Fire Suppression Systems, and Structural Detailed Engineering Assessments. These sessions provided detailed explanations of design review processes, required documentation, and core testing methods, and concluded with interactive Q&A rounds. Participants expressed their appreciation for the technical support and interest in continuing these initiatives in the future.

The Pakistan Accord Secretariat hosted two technical workshops for consultants in Lahore and Karachi.

Government Capacity Building Workshops - February 2025

The Pakistan Accord recently conducted capacity-building workshops for government officials in Sindh and Punjab. Held in Karachi from February 3–7, 2025, and in Lahore from February 10–14, 2025, the five-day events brought together over 70 participants from multiple government departments. Expert-led sessions by Arup covered key topics such as building, fire, and electrical safety, along with practical factory visits that provided hands-on insights into regulatory processes and international standards.

Officials including Dr. Abid Shaikh, Athar Ali Shah, Dr. Rizwan Naseer, and Syeda Kulsoom Hayee, inaugurated and closed the sessions, underscoring the initiative’s importance in fostering a stronger safety culture across Pakistan’s workplaces.

The capacity-building workshops for government officials covered key topics under building, fire, and electrical safety.

Implementation

The Pakistan Accord is actively building and training local teams in its Karachi and Lahore offices to ensure effective program implementation in close coordination with covered suppliers and brands. The organisation is also expanding both its Inspections & Remediation Department and Workplace Program Team. Furthermore, recruitment efforts are underway to hire fire, structural, and boiler safety experts, as well as training and complaints specialists, along with additional support staff.

See the latest vacancies under the Pakistan Accord.

Resources

Stay in Touch

Related updates

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.

October 22, 2025

This briefing provides updates on the number of signatory brands, factories and workers. Additionally, it includes guidance on the actions suppliers should take to address immediate safety findings.

November 24, 2025

The International Accord is saddened by the earthquake in Bangladesh and concerned about the reported injuries and loss of life. Our thoughts are with all affected individuals and families.

November 9, 2025

The International Accord is pleased to announce that, from mid-November 2025, the Worker Complaints Mechanism in Bangladesh will be expanded to cover issues beyond Occupational Safety and Health (OSH).

October 23, 2025

On 23 October 2025, the Pakistan Accord hosted a Brand-Supplier Roundtable at the Avari Hotel in Lahore, bringing together over 50 brand representatives and 30 key suppliers.